MODELA MDX-50 Benchtop Milling Machine

Benchtop Milling Machine

The MODELA MDX-50 benchtop milling machine by Roland DG combines precise, automated milling and unmatched ease-of-use. An ideal solution for short-runs and prototypes, the MDX-50 reduces operation time and simplifies production so users of all abilities can mill functional parts with incredible quality on a wide range of materials.

Distinguishing Features

- Advanced drive system supports dimensional stability

- Large machining area plus enhanced machine rigidity and drive mechanics

- Optional rotary axis rotates materials automatically from 0 to 360 degrees continuously or indexes for 2-sided, 4-sided and custom angles

- Simple-to-load tools and automatic machine calibration

- Requires no special electrical set-up and needs no additional air compressor

- Colour-coded LED status lights allow current job status to be monitored from a distance

- Built-in debris collection drawer with rail guided safety door for safe and clean production

- Ideal for use in studio and educational environments

Operator-Friendly Control and Software

Become a 3D milling expert almost immediately with the MDX-50’s simple yet powerful built-in control panel and virtual control panel (VPanel), and bundled SRP Player CAM software that’s easy-to-use and simplifies operation.

With the control panel at the front of the unit, almost all operations can be completed from the unit itself without having to go back to a PC. The VPanel interface operates seamlessly with the MDX-50 and allows users to make changes to spindle rotation or speed during operation.

The following items are just some of the materials that can be milled with the MDX-50 benchtop CNC mill:

- ABS

- POM

- Nylon Plastic Foam

- Modeling Wax

- PVC Plywood

- Hardwood

- Acetal

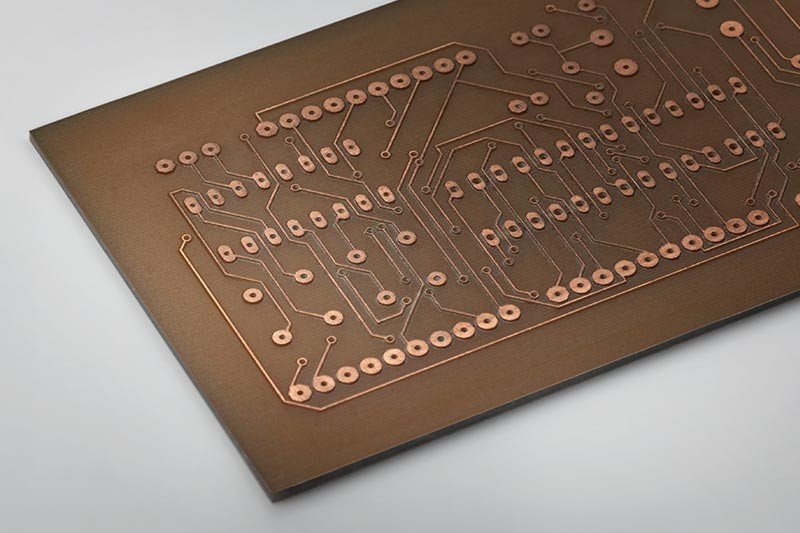

Mill Fine Details and Smooth Finishes

With an improved drive system, machine rigidity and enhanced drive mechanics, the MDX-50 mills incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 400mm (X) x 305mm (Y) x 135mm (Z) supports production of large single objects or batch production of smaller multiple parts.

Free Your Time

The automated features of the MDX-50 enables users to mill with speed and confidence. Combine the 5-station ATC and optional rotary axis unit for the most automated and precise operation:

- Auto-sensing function corrects the tool length to ensure milling accuracy for every job

- Optional rotary axis for effortless production of complex surfaces:

- Includes a wide, self-centering headstock and tailstock workpiece clamps

- Auto-rotates materials from 0-to-360 degrees

- Indexes for 2-sided, 4-sided and custom angles

The Peace of Mind That Comes with Buying a Roland DG

Like all Roland DG products, the MDX-50 was designed and manufactured at a state-of-the-art, ISO-certified facility. With a 3 Year Parts ‘n All Warranty, you have the peace of mind knowing your device is backed by one of the most comprehensive warranty packages in the industry

Download Brochure

Benchtop Milling Machine

The MODELA MDX-50 benchtop milling machine by Roland DG combines precise, automated milling and unmatched ease-of-use. An ideal solution for short-runs and prototypes, the MDX-50 reduces operation time and simplifies production so users of all abilities can mill functional parts with incredible quality on a wide range of materials.

Distinguishing Features

- Advanced drive system supports dimensional stability

- Large machining area plus enhanced machine rigidity and drive mechanics

- Optional rotary axis rotates materials automatically from 0 to 360 degrees continuously or indexes for 2-sided, 4-sided and custom angles

- Simple-to-load tools and automatic machine calibration

- Requires no special electrical set-up and needs no additional air compressor

- Colour-coded LED status lights allow current job status to be monitored from a distance

- Built-in debris collection drawer with rail guided safety door for safe and clean production

- Ideal for use in studio and educational environments

Operator-Friendly Control and Software

Become a 3D milling expert almost immediately with the MDX-50’s simple yet powerful built-in control panel and virtual control panel (VPanel), and bundled SRP Player CAM software that’s easy-to-use and simplifies operation.

With the control panel at the front of the unit, almost all operations can be completed from the unit itself without having to go back to a PC. The VPanel interface operates seamlessly with the MDX-50 and allows users to make changes to spindle rotation or speed during operation.

The following items are just some of the materials that can be milled with the MDX-50 benchtop CNC mill:

- ABS

- POM

- Nylon Plastic Foam

- Modeling Wax

- PVC Plywood

- Hardwood

- Acetal

Mill Fine Details and Smooth Finishes

With an improved drive system, machine rigidity and enhanced drive mechanics, the MDX-50 mills incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 400mm (X) x 305mm (Y) x 135mm (Z) supports production of large single objects or batch production of smaller multiple parts.

Free Your Time

The automated features of the MDX-50 enables users to mill with speed and confidence. Combine the 5-station ATC and optional rotary axis unit for the most automated and precise operation:

- Auto-sensing function corrects the tool length to ensure milling accuracy for every job

- Optional rotary axis for effortless production of complex surfaces:

- Includes a wide, self-centering headstock and tailstock workpiece clamps

- Auto-rotates materials from 0-to-360 degrees

- Indexes for 2-sided, 4-sided and custom angles

The Peace of Mind That Comes with Buying a Roland DG

Like all Roland DG products, the MDX-50 was designed and manufactured at a state-of-the-art, ISO-certified facility. With a 3 Year Parts ‘n All Warranty, you have the peace of mind knowing your device is backed by one of the most comprehensive warranty packages in the industry

Download Brochure

Benchtop Milling Machine

The MODELA MDX-50 benchtop milling machine by Roland DG combines precise, automated milling and unmatched ease-of-use. An ideal solution for short-runs and prototypes, the MDX-50 reduces operation time and simplifies production so users of all abilities can mill functional parts with incredible quality on a wide range of materials.

Distinguishing Features

- Advanced drive system supports dimensional stability

- Large machining area plus enhanced machine rigidity and drive mechanics

- Optional rotary axis rotates materials automatically from 0 to 360 degrees continuously or indexes for 2-sided, 4-sided and custom angles

- Simple-to-load tools and automatic machine calibration

- Requires no special electrical set-up and needs no additional air compressor

- Colour-coded LED status lights allow current job status to be monitored from a distance

- Built-in debris collection drawer with rail guided safety door for safe and clean production

- Ideal for use in studio and educational environments

Operator-Friendly Control and Software

Become a 3D milling expert almost immediately with the MDX-50’s simple yet powerful built-in control panel and virtual control panel (VPanel), and bundled SRP Player CAM software that’s easy-to-use and simplifies operation.

With the control panel at the front of the unit, almost all operations can be completed from the unit itself without having to go back to a PC. The VPanel interface operates seamlessly with the MDX-50 and allows users to make changes to spindle rotation or speed during operation.

The following items are just some of the materials that can be milled with the MDX-50 benchtop CNC mill:

- ABS

- POM

- Nylon Plastic Foam

- Modeling Wax

- PVC Plywood

- Hardwood

- Acetal

Mill Fine Details and Smooth Finishes

With an improved drive system, machine rigidity and enhanced drive mechanics, the MDX-50 mills incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 400mm (X) x 305mm (Y) x 135mm (Z) supports production of large single objects or batch production of smaller multiple parts.

Free Your Time

The automated features of the MDX-50 enables users to mill with speed and confidence. Combine the 5-station ATC and optional rotary axis unit for the most automated and precise operation:

- Auto-sensing function corrects the tool length to ensure milling accuracy for every job

- Optional rotary axis for effortless production of complex surfaces:

- Includes a wide, self-centering headstock and tailstock workpiece clamps

- Auto-rotates materials from 0-to-360 degrees

- Indexes for 2-sided, 4-sided and custom angles

The Peace of Mind That Comes with Buying a Roland DG

Like all Roland DG products, the MDX-50 was designed and manufactured at a state-of-the-art, ISO-certified facility. With a 3 Year Parts ‘n All Warranty, you have the peace of mind knowing your device is backed by one of the most comprehensive warranty packages in the industry

Download Brochure